China OEM High Speed Friction Feeder - Standard intelligent card feeding machine – Baiyi

China OEM High Speed Friction Feeder - Standard intelligent card feeding machine – Baiyi Detail:

Feature

Standard intelligent card feeding machine, is developed according to packing industry requirement, which integrated key technology of Intelligent feeding. It is one size small, weight light intelligent feeding system. It is suit for feeding certificate of conformity, label, manual, paper etc. then to be used on kinds of packing production line. Compared with normal feeding machine, it has obvious product adaptability, installation convenience, high-speed response performance, very high feeding accuracy and fully open communication port, which is convenient for independent control or net-working, especially suit for manual replacement and realize unmanned workshop.

It is configured with double sheet detection and page link detection, material jammed detection, no material then alarm function. The control is HMI and PLC. The technical parameter setting is simple, easy on operation which is very popular by users. The applicability is good especially for folded product and organ folded product. Double detection with alarm & machine stop function, counting, to feed according to the set quantity & time, no material alarm and machine stop function, inner control or control from outside trigger function. It with all the listed functions.

Standard intelligent feeding machine has two model at present. 1. It is directly feeding(model: BY-HFT250); 2, feeding with conveyor(model: BY-HTF250S). integrated several intelligent feeders to auto feeding & sorting system. Because of the integration difference, there are 3 models: 1. T type stepping sorting system (model: BY-MFJ3000-06); 2. – type stepping sorting system (model: BY-MFJ6000-07); 3. –type continuous sorting system (Model: BY-MFJ6000-06)

The difference between“Direct delivery feeder” and “ delivery feeder with conveyor”is with or without conveyor. Direct delivery is without conveyor, which is convenient for direct installation and product feeding but it can’t install other technology equipment such as identification equipment, collection equipment etc. while delivery feeder with conveyor has conveyor, it needs to pass a short conveyor then do the delivery, which is convenient for identification equipment and collection equipment’s installation. Several intelligent feeders can be integrated to auto feeding & sorting system. The three integration method can be selected according to the application requirement. Users can choose to adopt stainless steel as a outside shape or painted carbon steel. Color can be customized.

Reference Drawing

1. direct delivery feeder drawing

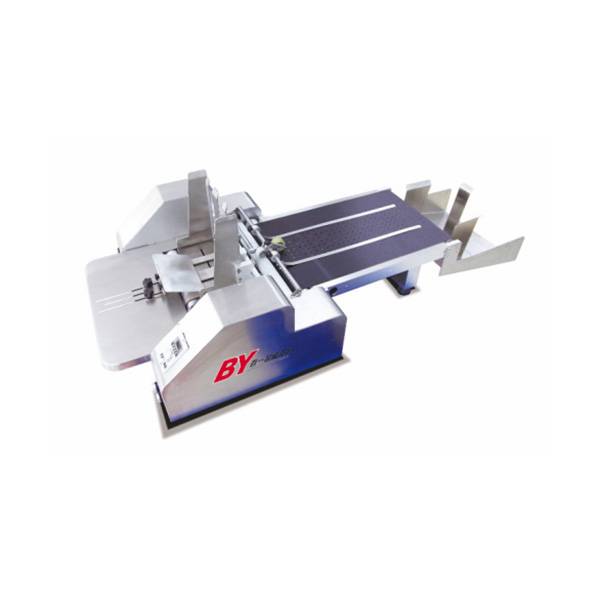

2. delivery feeder with conveyor drawing

3. T type stepping & sorting system drawing

4. type stepping & sorting systemdrawing

5. type continuous sorting system

Technical Parameter

1. direct delivery feeder technical parameter

A. out dimension: L * W * H = 485 * 563 * 345mm(without conveyor)

B. weight: 20KG

C. Voltage: 220VAC, 50/60HZ

D. power: about 500W

E. efficiency: 0-300pcs/min(take 100mm size product for reference)

F. conveyor running speed: 0-50m/min(can continuously adjustment)

G. available product size: L * W * H = 55-200 * 50-250 * 0.1-3mm

H. Speed adjustment way: HMI+PLC

I. motor &transmission: servo + timing belt

J. product stack height: 100mm or 200PCS(it is related with the real product)

K. suitable product type or specification: kinds of single catalogue, folded paper, cards, manual, labels, books.

L. machine body material: stainless steel or painted carbon steel (color can be customized).

M. installation way: independent installation, desktop.

N. special function: double detection, product link detection, no material detection and alarm, card material detection and alarm.

2. delivery feeder with conveyor technical parameter

A. dimension: L * W * H = 685 * 370 * 485mm,(with conveyor)

B. weight: 25KG

C. Voltage: 220VAC, 50/60HZ

D. power: about 500W

E. efficiency: 0-300pcs/min(take product size 100mm for reference)

F. belt running speed: 0-50m/min(continuous adjustment)

G. available product size: L * W * H = 55-200 * 50-250 * 0.1-3mm

H. speed control method: HMI+PLC

I. motor & transmission: servo & timing belt

J. material stack height: 100mm or 200PCS(depends on the real product)

K. available product: kinds of catalogue page, folded paper, cards, manual, labels, books.

L. machine body material: stainless steel or carbon steel with painting(color can be customized)

M. installation method: independent installation, desktop

N. special function: double detection, link page detection, no material detection & alarm, material jammed alarm.

3. T type stepping sorting system’s technical parameter

A. dimension: L * W * H = 3500 * 860 * 1220mm

B. weight: 700KG

C. voltage: 220VAC, 50/60HZ

D. power: about 2.0KW

E. efficiency: 0-3000set/min(take the product size 100mm for reference)

F. belt running speed: 0-30m/min(can be adjusted step by step)

G. available product size: L * W * H = 40-180 * 60-140 * 0.05-3mm

H. speed control method: HMI+PLC+PC

I. motor & transmission: servo & timing belt

J. available product: kinds of catalogue page, folded paper, cards, manual, labels, books.

L. machine body material: stainless steel or carbon steel with painting(color can be customized)

M. installation method: independent installation, floor-standing

N. special function: double detection, link page detection, no material detection & alarm, material jammed alarm.

O. kinds of product per set: 6 kinds of product per set (it can be customized making)

4. type stepping & sorting system technical parameter

A. dimension: L * W * H = 3500 * 700 * 1220mm

B. weight: 700KG

C. voltage: 220VAC, 50/60HZ

D. power: about 2.0KW

E. efficiency: 0-6000set/min(take the product size 100mm for reference)

F. belt running speed: 0-30m/min(step by step)

G. available product size: L * W * H =40-180 * 60-140 * 0.05-3mm

H. speed control method: HMI+PLC+PC

I. motor & transmission: servo & timing belt

J. available product: kinds of catalogue page, folded paper, cards, manual, labels, books.

L. machine body material: stainless steel or carbon steel with painting(color can be customized)

M. installation method: independent installation, floor-standing

N. special function: double detection, link page detection, no material detection & alarm, material jammed alarm.

O. kinds of product per set: 7 kinds product per set (it can be customized making)

5. type continuous sorting system’s technical parameter

A. dimension: L * W * H =5500 * 700 * 950mm

B. weight: 700KG

C. voltage: 220VAC, 50/60HZ

D. power: about 2.0KW

E. efficiency: 0-6000set/min(take product size 100mm for reference)

F. belt running speed: 0-35m/min(continuous running)

G. available product size: L * W * H = 55-200 * 50-200 * 0.1-3mm

H. speed control method: HMI+PLC+PC

I. motor & transmission: servo & timing belt

J. available product: kinds of catalogue page, folded paper, cards, manual, labels, books.

L. machine body material: stainless steel or carbon steel with painting(color can be customized)

M. installation method: independent installation, floor-standing

N. special function: double detection, link page detection, no material detection & alarm, material jammed alarm.

O. kinds of product per set: 7 kinds product per set (it can be customized making)

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for China OEM High Speed Friction Feeder - Standard intelligent card feeding machine – Baiyi , The product will supply to all over the world, such as: New York, Spain, Danish, In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.