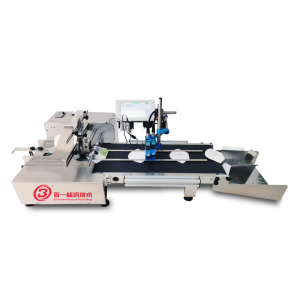

Customized intelligent friction feeder BY-HF02-800

There are many optional functions which can be selected below:

1.Input conveyor: it solves the problem of the product heavy. It can reduce the pressure on the friction belt. Because of friction principle, people can’t input a lot of products into the feeding magazine, otherwise the feeding would be effected. Meanwhile it is helpful to reduce labor cost. If the feeding speed is not so fast, one operator can well manage the feeding and collection.

2.Double detection: it is our invention patent and it can do the inspection according to the product thickness. It can do the inspection for single layer or multiple layer product. And the inspection accuracy is 0.1mm.

3.Alignment: it is good for customer who has a serious printing quality requirement on the product and it is to correct the product feeding position which came from the gap between the feeding magazine plate to the product. the product pass through this device and the bias can be +/-0.2mm;

4.Normal conveyor: it is with pressing bar.

5.Rejection device: it adopts flip-over rejection device which is good for cement bags.

6.Speed up conveyor, which is to make sure that the product can go on the vertical collection conveyor smoothly.

7.Vertical stack collection conveyor: it is controlled by a unique electrical box with PLC & HMI. Users can do the setting freely that how many pcs product stacked then move forward.

Technical parameter

1. Dimension:L*W*H=6700*1260*1250mm

2. Weight:about 900KG

3. Voltage:220VAC, 50HZ/60HZ.

4. Power:about 2000W

5. efficiency:0-300pcs/min(take the product size 100mm for reference)

6. conveyor belt running speed:0-70m/min(can be adjusted continuously)

7. available product size:L*W*H=(60-400)*(30-780)*(0.1-3)mm

8. speed adjustment:transformer or Brushless DC motor.

9. motor:transformer motor or Brushless DC motor

10. available product:various paper box, paper bags, cards, labels, tags, plastic bags, instructions etc.

11. body material:stainless steel

12. installation method:installation separately, floor stand.

Here is the drawing below for your reference: