Manufacturer for Standard Feeder - Standard rewinder with TTO printer – Baiyi

Manufacturer for Standard Feeder - Standard rewinder with TTO printer – Baiyi Detail:

Introduction

This intelligent printing & rewinding series is for labels in roll, film in roll, paper in roll, woven label in roll etc. at present market’s coding requirement. According to material in roll’s rewinding & production feature and integrated kinds of products’ coding technology. Pursuing one machine for multiple purposes.——it can install TTO thermal printer and UV printer etc. “one machine with multiple functions”——satisfy kinds of technology requirement in kinds of industry. “one machine with diversification”——continuous or intermittent feeding, structure is modular, people can select the configuration according to their production requirement. It is the best selection for material in roll. According to present industry requirement and technology feature, it has standard TTO thermal printing rewinder, standard UV printing rewinder, high speed rewinder. People can choose to use CIJ, or TIJ printer, laser printer, TTO thermal printer and UV printing system for coding according to coding requirement.

“standard TTO thermal printing rewinder” is developed according to thermal printing technology feature, equipped with TTO printing roller and printing mounting bracket. HMI adopts 7inch colorful touch screen, PLC and micro PC for controlling. According to kinds of films and labels structure and feature difference, people can set working parameter in HMI and monitor the working status and give alarm. Controlling system’s linear un-winding and winding tension, fast/slow lifting, shut-down prevention, white mark or colorful mark’s trigger sensing, counting etc. all function, really realized intelligent control.

“standard UV printing rewinder” development is according to UV printing system’s technology feature, it can install printing system, plasma and LED curing. HMI adopts 7 inch colorful touch screen, PLC and micro PC for control. According to kinds of films and labels structure and feature difference, people can set working parameter in HMI and monitor the working status and give alarm. Controlling system’s linear un-winding and winding tension, fast/slow lifting, shut-down prevention, white mark or colorful mark’s trigger sensing, counting etc. all function, really realized intelligent control. “high speed rewinder”is based on the standard rewinder, speed is greatly improved and stable speed can be 100m/min. it belongs to special occasions.

Optional function: ”auto rectify system“

Reference Drawing

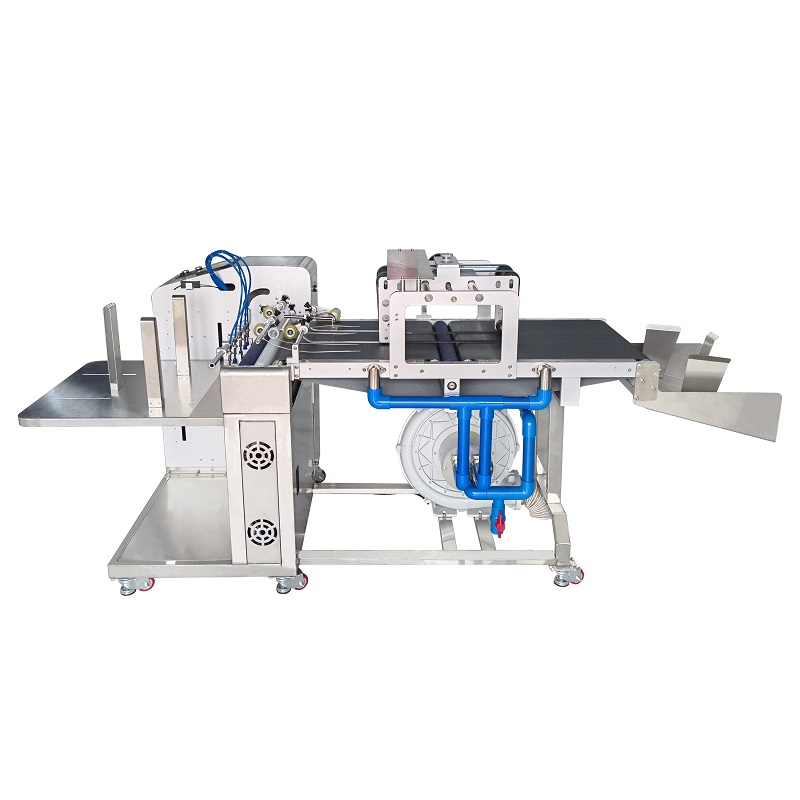

1. standard TTO thermal printing rewinder

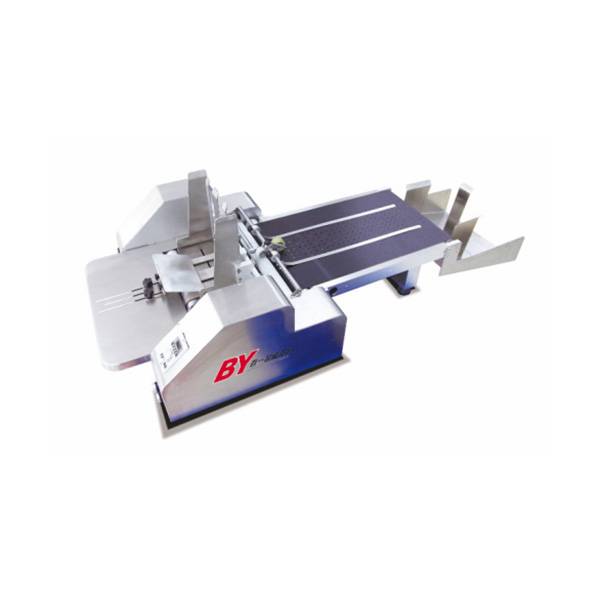

2. standard UV printing rewinder

3. high speed rewinder

Equipment Parameter

1. standard TTO thermal printing rewinder

A. dimension: L * W * H = 1200 * 1100 * 1200mm

B. weight: 300KG

C. voltage: 220VAC 50/60HZ

D. power: about 2KW

E. efficiency: about 200pcs/min(it takes product 100mm for reference, it is also related with printing speed and frequency.)

F. belt running speed: 2-60m/min(continuously adjustment)

G. available product size: material width: 30-480mm, Max material diameter 500mm; Max weight for material 50KG

H. rectify: framework rectify (optional function) and the accuracy is ±0.25mm

I. motor: servo motor

J. available product: BOPP, CPP, PET, PE, paper, composite film, aluminized film etc. material in roll.

K. releasing tension control: linear tension control

L. collection tension control: linear tension control

M. core diameter: 3inch(76mm)

N. machine body: stainless steel or carbon steel with painting(color can be customized)

O. installation method: floor-stand installation, offline.

P. optional function: auto rectify system.

2. standard UV printing rewinder

A. dimension: L * W * H = 1200 * 1100 * 1200mm

B. weight: 300KG

C. voltage: 220VAC 50/60HZ

D. power: about 2KW

E. efficiency: about 200pcs/min(it takes product 100mm for reference, it is also related with printing speed and frequency.)

F. belt running speed: 2-60m/min(continuously adjustment)

G. available product size: material width :30-480mm, Max material diameter 500mm; Max weight for material 50KG

H. rectify: framework rectify (optional function) and the accuracy is ±0.25mm

I. motor: servo motor

J. available product: BOPP, CPP, PET, PE, paper, composite film, aluminized film etc. material in roll.

K. releasing tension control: linear tension control

L. collection tension control: linear tension control

M. core diameter: 3inch(76mm)

N. machine body: stainless steel or carbon steel with painting(color can be customized)

O. installation method: floor-stand installation, offline.

P. optional function: auto rectify system.

3. high speed rewinder

A. dimension: L * W * H = 1600 * 1150 * 1070mm

B. weight: 800KG

C. voltage: 220VAC 50/60HZ

D. power: about 2KW

E. efficiency: about 100-1000pcs/min( it takes product 100mm for reference, it is also related with printing speed and frequency.)

F. belt running speed: 10-100m/min(continuous adjustment)

G. available product: material width 30-440mm, max material diameter 450mm; max material weight 50KG

H. rectify: framework rectify (optional function) and the accuracy is ±0.25mm

I. motor: single phase frequency motor

J. available product: BOPP, CPP, PET, PE, paper, composite film, aluminized film etc. material in roll.

K. releasing tension control: constant tension control

L. collection tension control: constant tension control

M. core diameter: 3inch(76mm)

N. machine body: stainless steel or carbon steel with painting(color can be customized)

O. installation method: floor-stand installation, offline.

P. optional function: auto rectify system.

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Manufacturer for Standard Feeder - Standard rewinder with TTO printer – Baiyi , The product will supply to all over the world, such as: Leicester, Mauritius, Lisbon, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.