Vacuum feeding & TTO thermal printing all in one

Product introduction

Feeding & TTO thermal printing all in one series product is TTO thermal printing & intelligent feeding technology’s innovation integration. It realized auto feeding & TTO thermal printing’s coding perfectly and can be equipped with kinds of TTO thermal printer. It is for kinds of plastic bags, paper, label etc. soft material’s coding. Adopts ribbon as printing substrate, sanitary & convenient, economical , physical characters beautiful. Classic “ three phases” design mode: 1,auto feeding;2,TTO thermal printing;3,collection in hopper;layout simple, operation & maintenance easy, scalability strong. according to application requirement in the market, there are four types: 1. Classic feeding & TTO thermal printing all in one , Model: BY-TF01-TTO; 2. Standard feeding & TTO thermal printing all in one, Type A, Model: BY-TF01/02-TTO-A; 3. Standard feeding & TTO thermal printing all in one, Type B, Model: BY-TF01/02-TTO-B;4,normal feeding & TTO thermal printing all in one, model :BY-SF01-TTO. 5. Vacuum feeding & TTO thermal printing all in one.

Intelligent vacuum feeding & TTO thermal printing all in one adopts up-cup suction feeding principle to realize auto product feeding. The most difference with the standard intelligent feeding & TTO thermal printing all in one is that the vacuum feeding adopts vacuum cup for feeding & delivery. and the feature is that it can load a lot of product at one time, well protected the product surface, the structure is complex and stable, but the speed is not so fast.

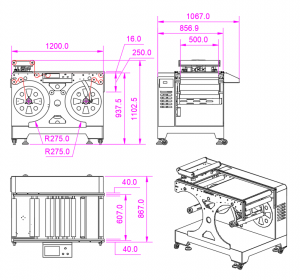

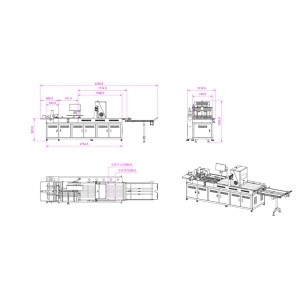

Here attached the picture below for reference:

Technical Parameter

1, Power supply:220VAC

2, power:about1.5KW(including one pump);

3, weight:200kg

4, dimension as the drawing below;

5, conveyor speed:0-50m/min

6, control method:PLC+ frequency transformer or DC brushless speed controller

7, feeding method:up- suction method with material up feeding.

8, The material stack height: about 200mm,and the correct value is according to the real testing.

9, Double detection accuracy:+-0.1mm(an optional function)

To know more about this product, pls get in touch with Ms. Easy. Email: ouyanghuihong@vip.163.com and whatsApp: +8613435663216